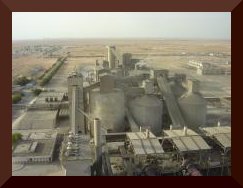

LaFarge, the largest worldwide producer of cement, is working very hard on reducing its own carbon footprint. The problem is that their footprint is very large. Heating limestone and shale to 1500° C cannot be done with a small hot plate. One of their economic goals is to use less petroleum products to make cement. Right now, almost 11% of their energy comes from alternative sources. Most of it comes from local waste when the public infrastructure can supply it. Tires, coffee, rice husks, and even bonemeal are used to heat their kilns.

LaFarge, the largest worldwide producer of cement, is working very hard on reducing its own carbon footprint. The problem is that their footprint is very large. Heating limestone and shale to 1500° C cannot be done with a small hot plate. One of their economic goals is to use less petroleum products to make cement. Right now, almost 11% of their energy comes from alternative sources. Most of it comes from local waste when the public infrastructure can supply it. Tires, coffee, rice husks, and even bonemeal are used to heat their kilns.

But alternative sources are not enough. LaFarge is also sponsoring research in creating new concrete formulas that take less energy to create. That research will take years. The current estimate is 5 years. Franz-Josef Ulm’s research into the nanostructure of cement may be the answer. If his team can find other materials or other techniques that can create the same “nano-bonds” as cement and use less energy, maybe the new cement can become only 2% of all CO2 emissions.

great post!